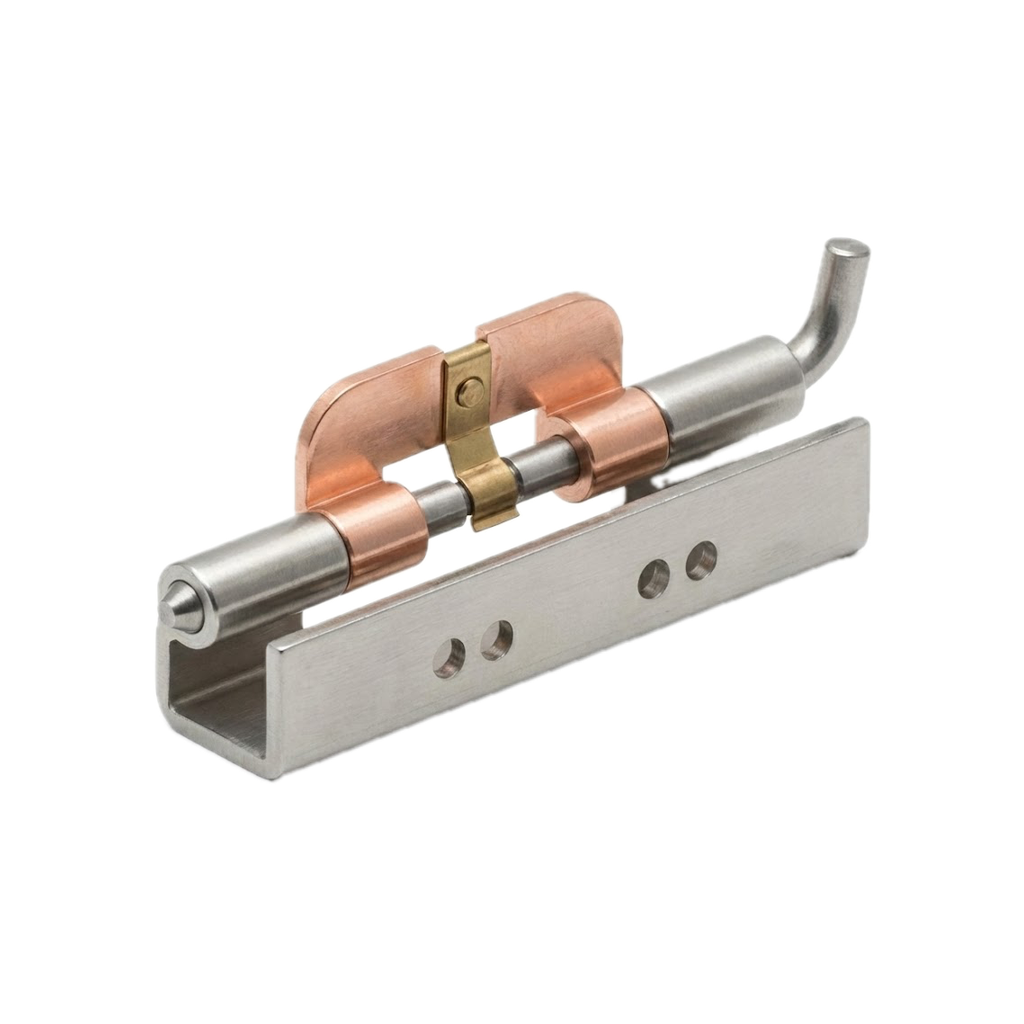

In products such as panel hinges, intermediate connection parts, and locking plastics, dimensional precision and durability are critical. At Mete Kalip, we manage tooling and contract press manufacturing to the same quality standard from the design and development stage. This supports electrical panel manufacturers with part fit, assembly ease, and long service life in mass production. The hinge and connection part samples in our project gallery are concrete evidence of our repeatable production capability and surface quality.

Read moreIn production since 2000, Mete Kalip provides tooling and contract press manufacturing to more than 20 industries with 28 years of experience. Across product groups such as automotive, electrical, lighting, solar panels, hardware, window accessories, kitchen tools, and furniture, we plan tooling and mass production together to deliver cost and time advantages. Our engineering approach accurately analyzes sector-specific tolerance needs, increasing efficiency while protecting quality. This approach positions us as a reliable supplier for manufacturers who want to stand out online.

Read moreThe Services and Projects sections on the Mete Kalip website transparently present our design and development, tooling, and contract press manufacturing processes. Through the project gallery, you can review panel hinges, connection parts, and product examples tailored to different industries, and request a quick quote via the Contact page. This holistic structure allows material selection, tooling life, part repeatability, and delivery times to be managed under a single plan during product development. The SEO-friendly keywords we use help you quickly reach the tooling, contract press manufacturing, and product development services you are looking for.

Read more