Safety, durability, and assembly precision in electrical panels

Electrical panel accessories—such as panel hinges, intermediate connection parts, locking plastics, ventilation louvers, and mounting brackets—define the safety and ergonomics of the enclosure system. In these products, dimensional tolerance, strength, and surface quality directly affect both assembly speed and the service life of the final product. At Mete Kalip, we manage tooling and contract press manufacturing together, turning repeatable quality in mass production into a standard.

Critical points in tooling design

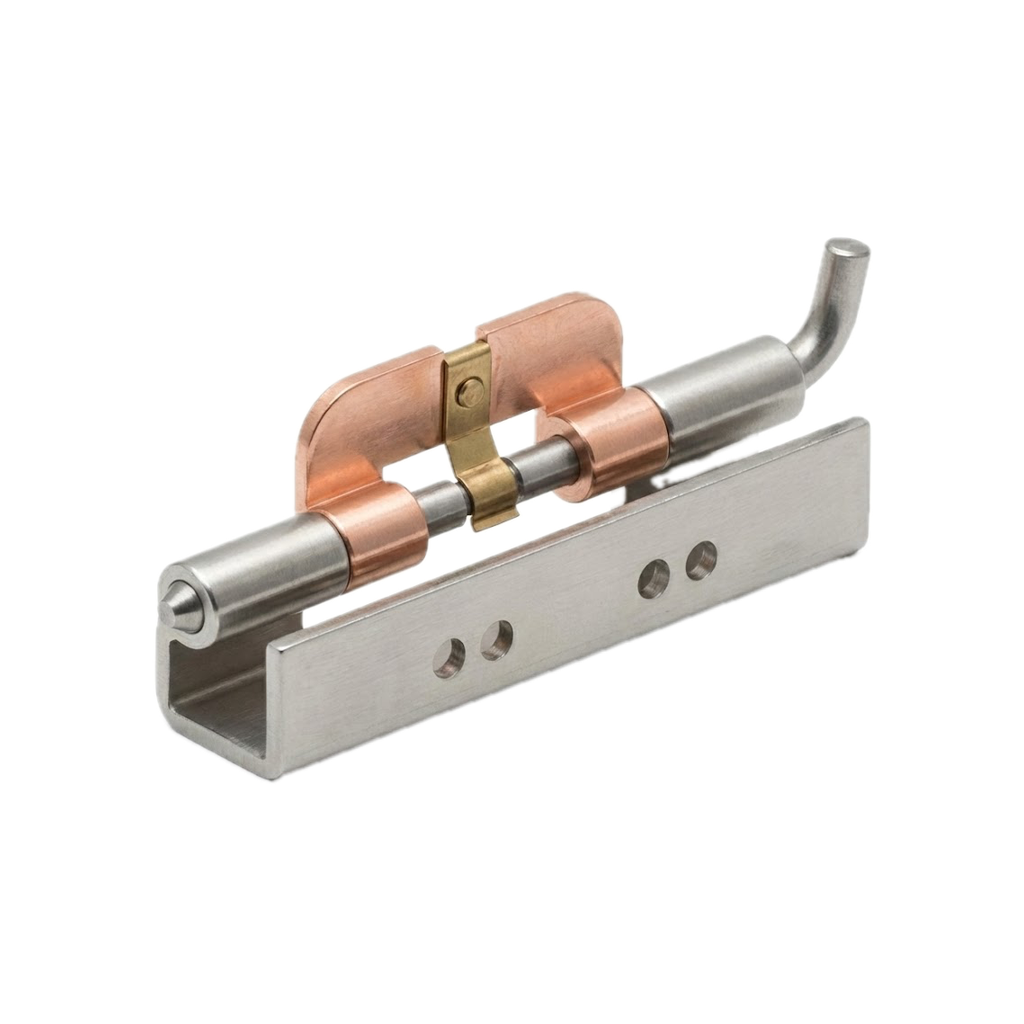

During tooling production, the operating environment, material, and assembly method are considered. Especially for load-bearing products like panel hinges and connection parts, tooling clearances and surface contacts are designed at the micron level. This approach reduces deformation during press forming, balances friction during assembly, and improves long-term performance.

Mete Kalip production approach

In production since 2000, Mete Kalip is a trusted solution partner in the tooling sector with 28 years of experience. With a dynamic in-house team and up-to-date technology investments, we manage both tooling and contract press manufacturing simultaneously. This ensures the technical standards defined at the start of a project are preserved in mass production as well.

- Panel hinges (vertical, concealed, wall-mounted)

- Panel intermediate connection parts and internal mounting elements

- Locking plastics, sliding locks, and lock accessories

- Panel ventilation louvers and cover parts

- Repeatable part tolerances

- Assembly ease and part compatibility

- Surface quality and long service life

- Process flow optimized for mass production

Consistency in mass production with contract press manufacturing

Supporting tooling with contract press manufacturing ensures continuity in electrical panel accessories. With per-piece checks and in-process monitoring, deviations are detected early. This reduces line stoppages, minimizes assembly errors, and keeps delivery schedules on track.

Projects and application examples

Products such as vertical panel hinges, concealed sheet-metal hinges, intermediate connection parts, and internal mounting parts on our Projects page demonstrate the solution variety required by electrical panel manufacturers. This variety proves our flexible production capacity for different panel types and assembly scenarios.

Reliable manufacturing partner for electrical panel accessories

We provide fast quotes and technical consulting for your tooling and contract press manufacturing needs.